M.M Player Piano restoration progress reports

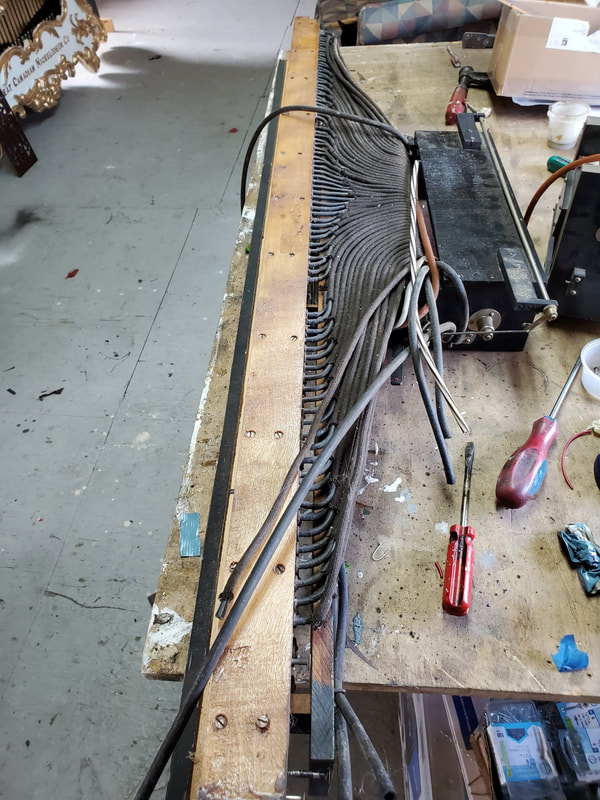

Restoration begins today with the lower pump section. This includes the documentation of the pumps and the ordering of any materials that may be needed as the restoration progresses.

Restoration starts with the big foot pumps July15 2021

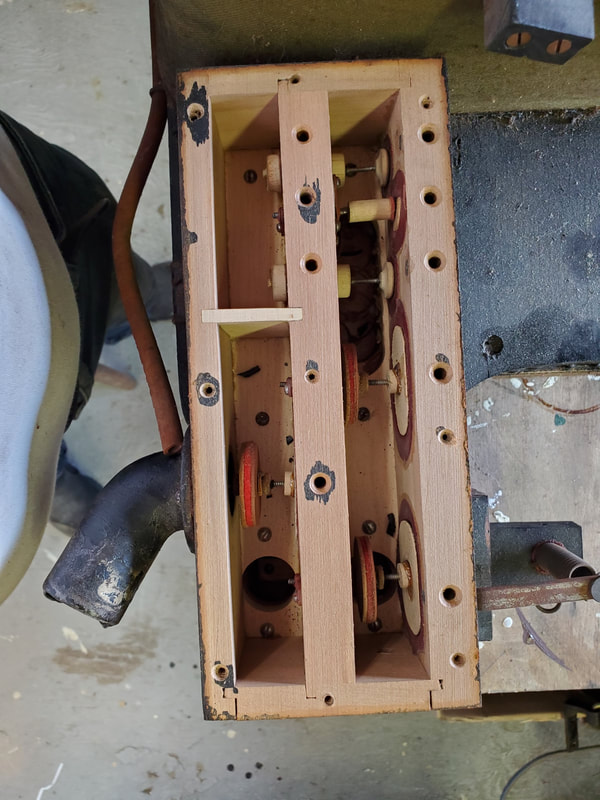

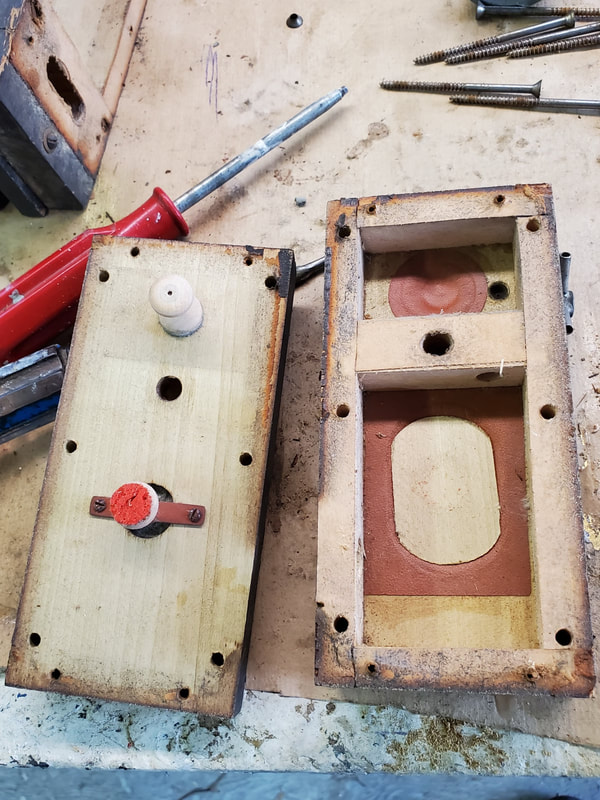

These pumps are constructed with a hard wood core then veneer is gluded on top. The main boards of the pumps are honey combed with air passages which takes the vacuum the pumps produces to the various items that operate the player piano "Stack"

The "Stack" is the box that sits on top of the key bed and makes the piano notes play according to the paper music roll.

Because the pump veneer is glued on with hot Hyde glue most often this glue is loose allowing vacuum to leak and not go to where it is intended. So we must actually break the pumps all apart and then rebuild after re-sealing all boards and replacing any damaged veneers and again we use the traditional hot Hyde glue.

This glue is used because it cures by loss of heat and not moisture like all other carpenter glues which of course warp the wood, so hot Hyde glue is used throughout the restoration

These pumps are constructed with a hard wood core then veneer is gluded on top. The main boards of the pumps are honey combed with air passages which takes the vacuum the pumps produces to the various items that operate the player piano "Stack"

The "Stack" is the box that sits on top of the key bed and makes the piano notes play according to the paper music roll.

Because the pump veneer is glued on with hot Hyde glue most often this glue is loose allowing vacuum to leak and not go to where it is intended. So we must actually break the pumps all apart and then rebuild after re-sealing all boards and replacing any damaged veneers and again we use the traditional hot Hyde glue.

This glue is used because it cures by loss of heat and not moisture like all other carpenter glues which of course warp the wood, so hot Hyde glue is used throughout the restoration

The

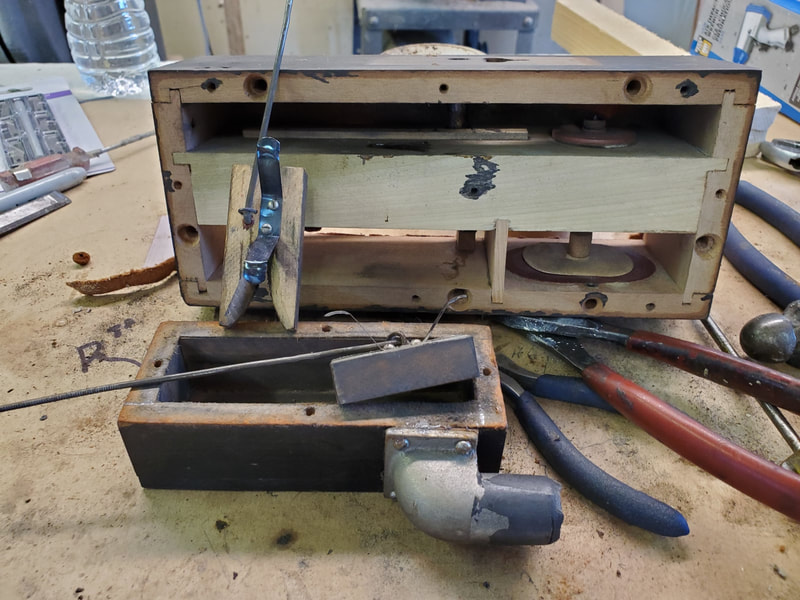

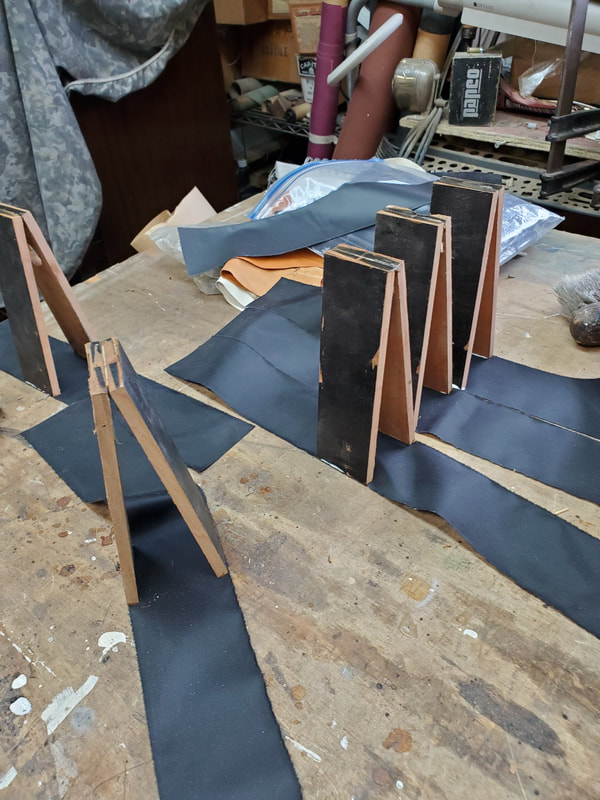

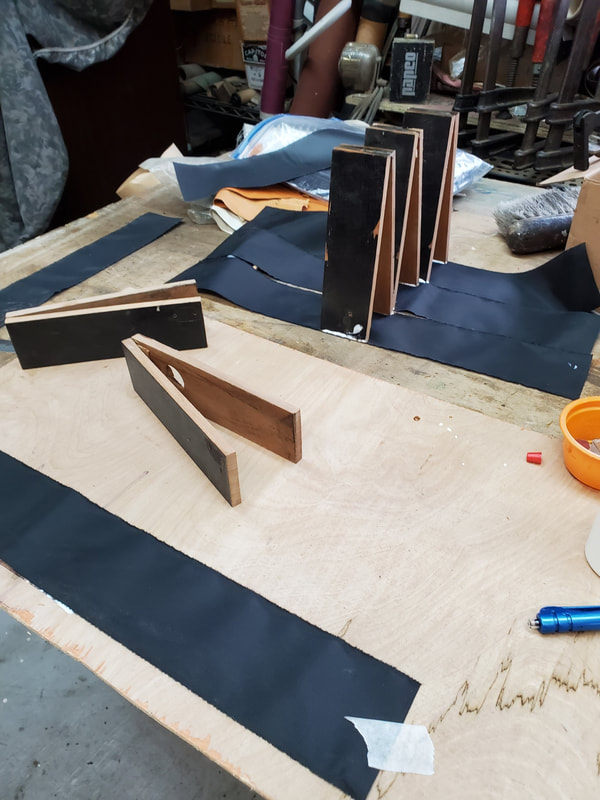

The restoration continues on the pumps with the removal of the two main bellows etc.

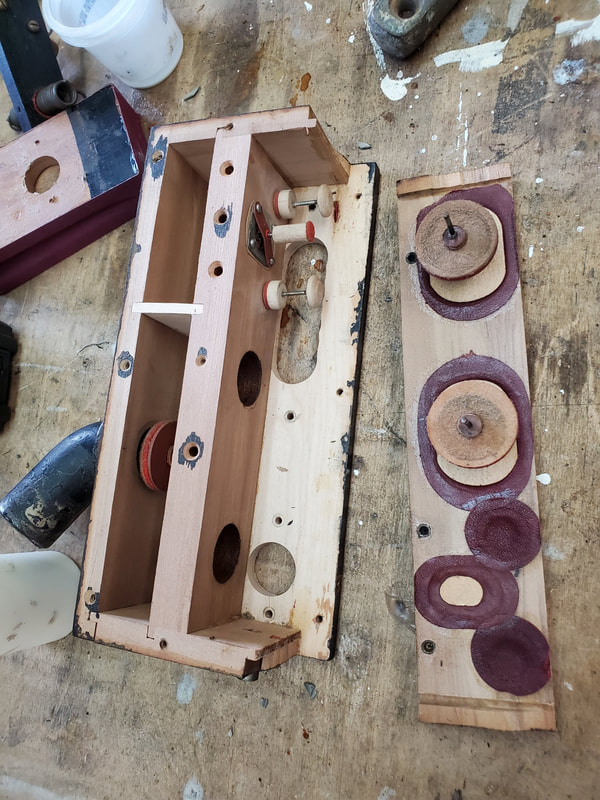

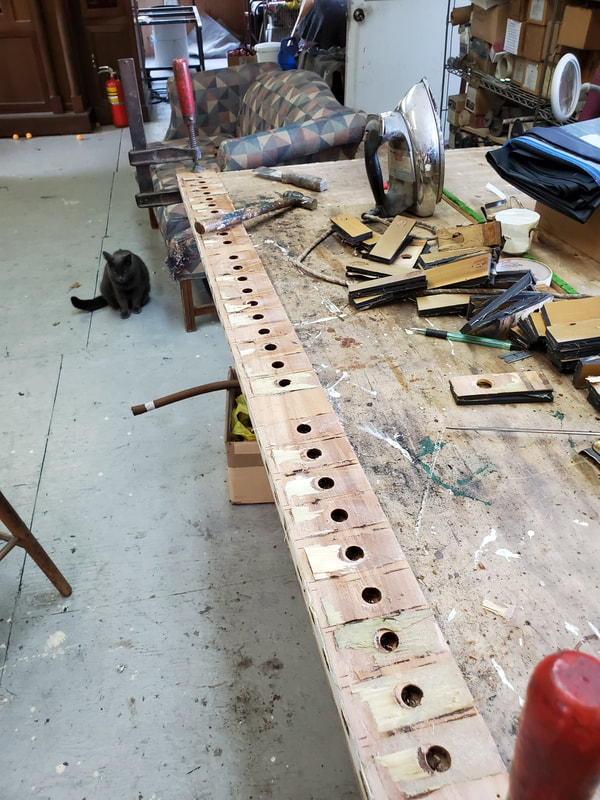

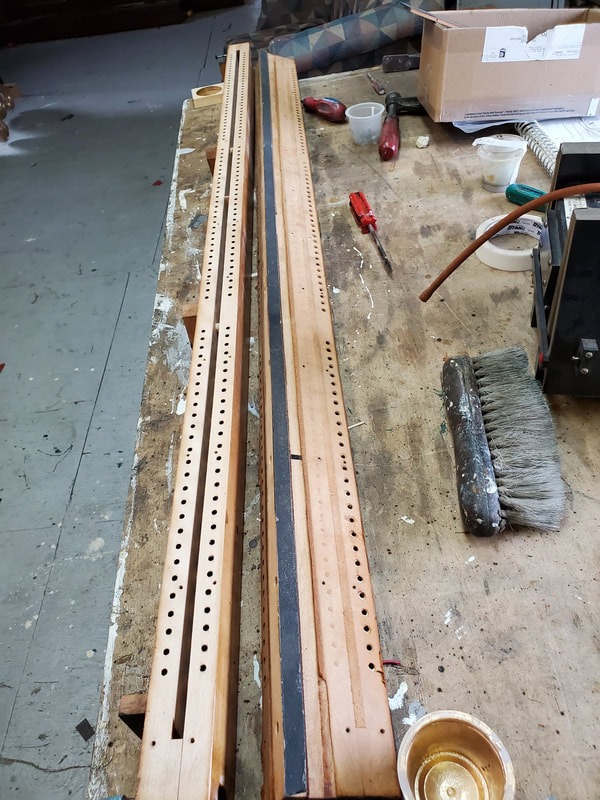

Because these pumps were built long before the invention of plywood, the builders used a solid wood plank usually made up of several boards glude together then covered with a 1/8" sheet of veneer. Unfortunately over 100 years of being dry in the winter and moist in the summer has caused this vineer to lift or crack and allow air to leak right through the bellows. So a great deal of time is spent simply regluing the various sections.

This week included the removal of the main bellows cloth, cutting new cloth and installing the cardboard gussets which stop the heavy bellows cloth from popping out when the pumps are under pressure. etc.

Because these pumps were built long before the invention of plywood, the builders used a solid wood plank usually made up of several boards glude together then covered with a 1/8" sheet of veneer. Unfortunately over 100 years of being dry in the winter and moist in the summer has caused this vineer to lift or crack and allow air to leak right through the bellows. So a great deal of time is spent simply regluing the various sections.

This week included the removal of the main bellows cloth, cutting new cloth and installing the cardboard gussets which stop the heavy bellows cloth from popping out when the pumps are under pressure. etc.

Aug 9 2021 work continues on the main pumps.

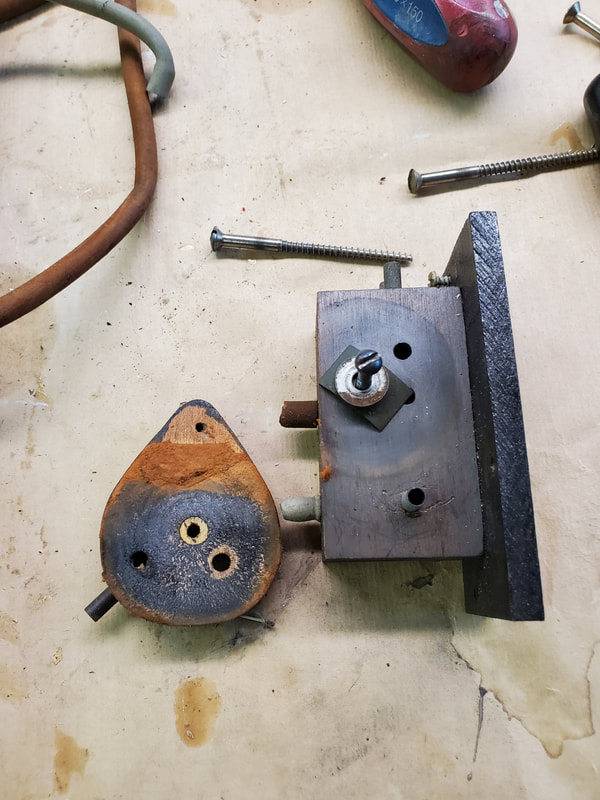

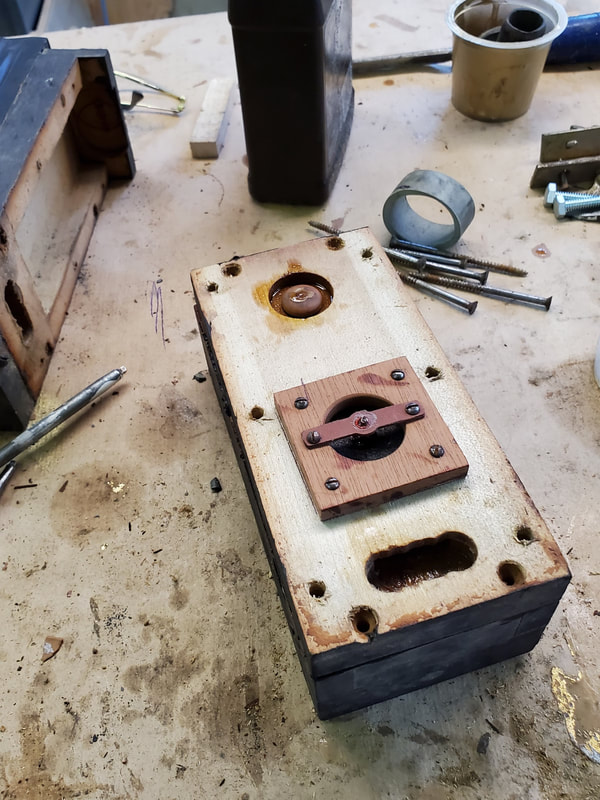

Aug 16 progress report; The pumps are nearing completion with most of the interior channels being sealed against leakage of vacuum, the main pumps and reservoirs now completed and the foot peddles. This week is the various control boxes etc.

Aug 24 2021 The main pumps are now completed and ready for testing and regulating.

Next is the player piano "Stack" which is the black box that sits above the piano keys and has the "spool box" which is where the paper music rolls are placed to play the instrument.

Next is the player piano "Stack" which is the black box that sits above the piano keys and has the "spool box" which is where the paper music rolls are placed to play the instrument.

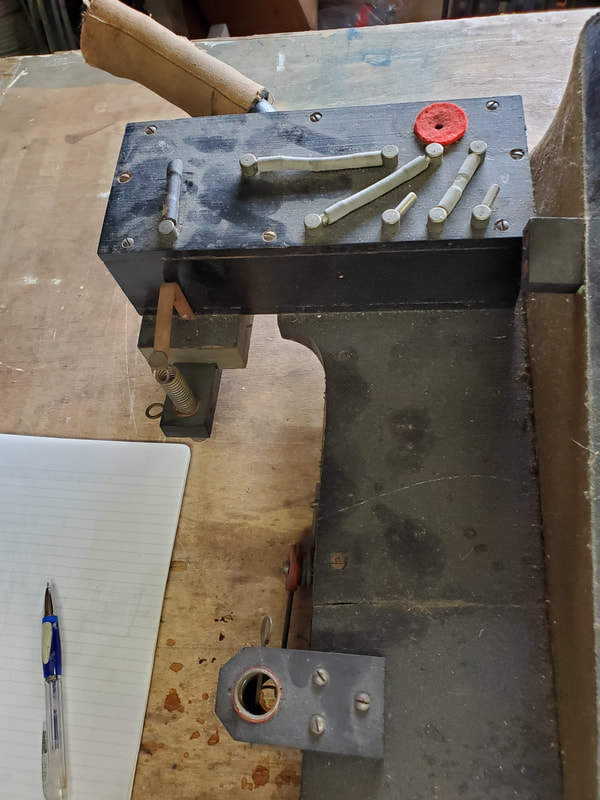

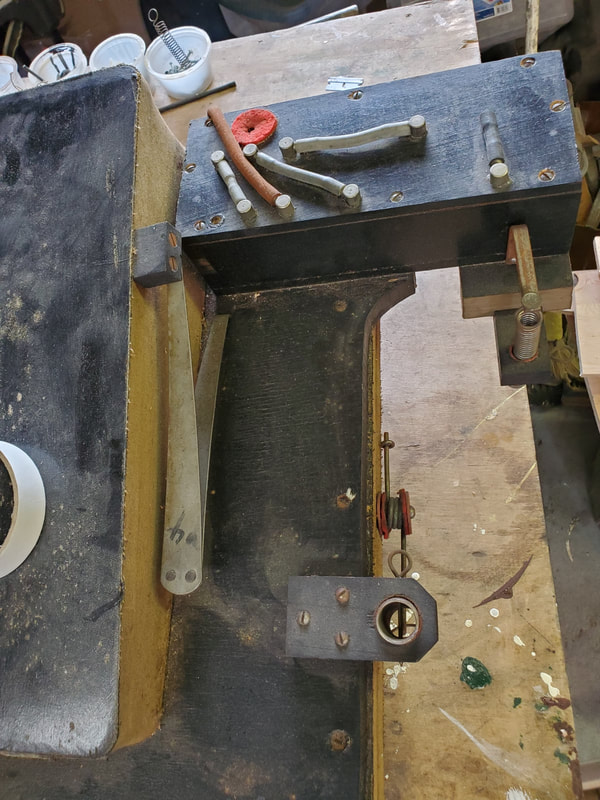

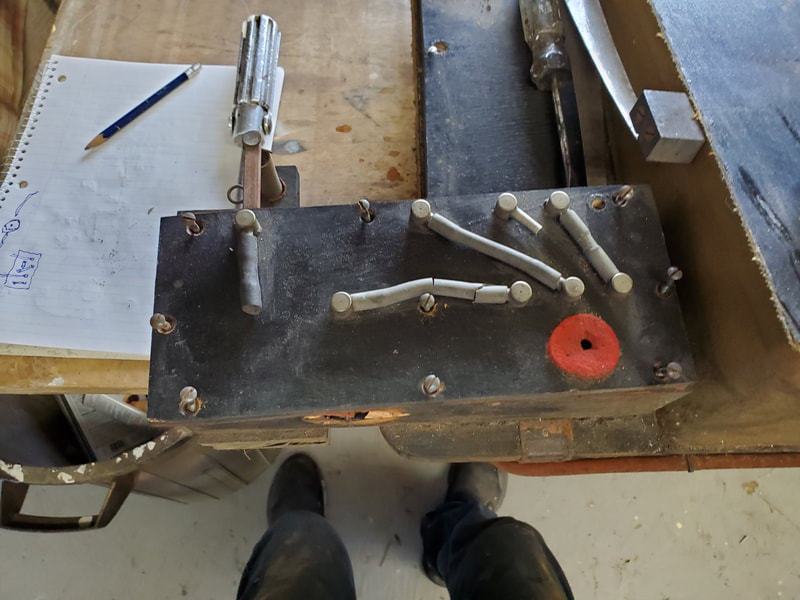

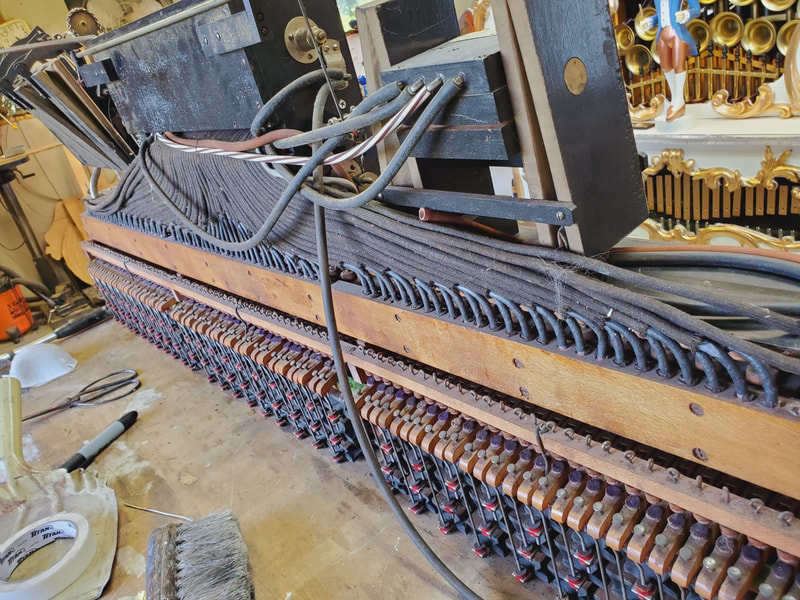

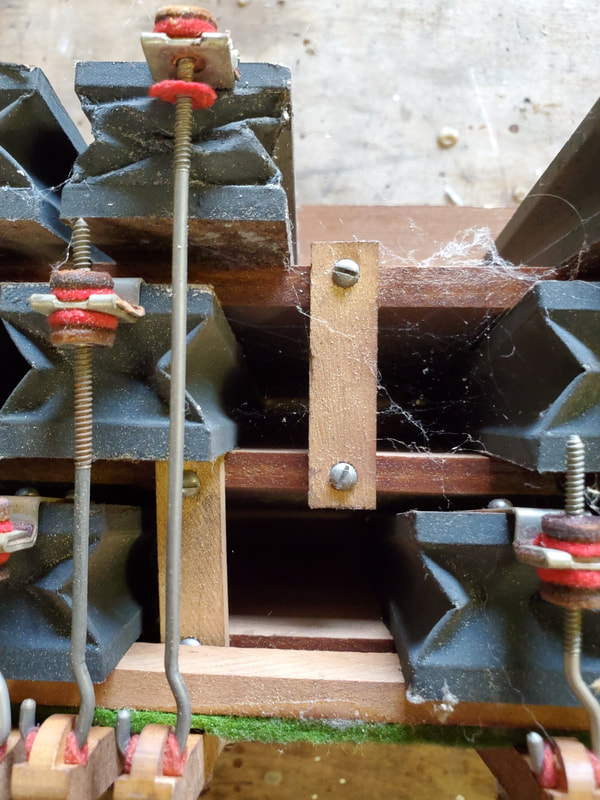

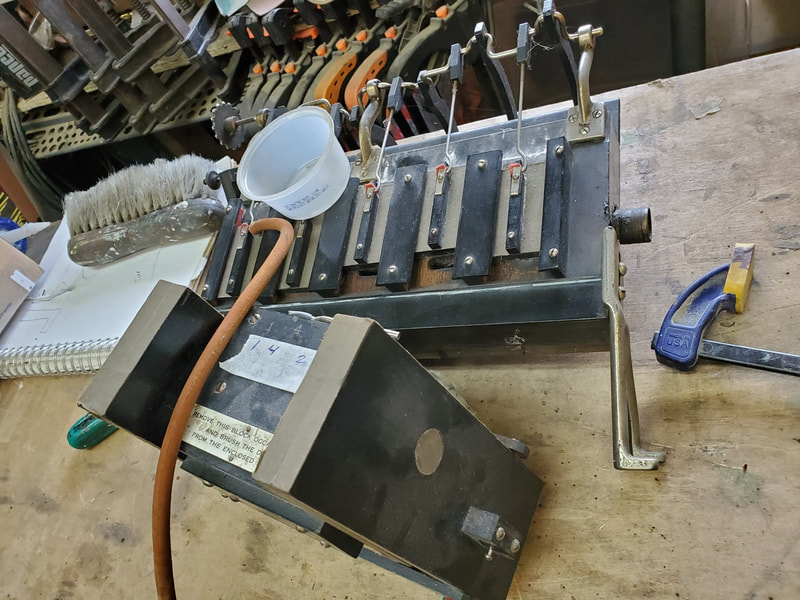

Sept 18/21 Restoration next moved to dismantling the player stack, as you can see the original builders did an amazing job to make this very complicated system very compact and able to read the perferations in the music roll and convert it into motion through a series of valves and pouches all of wood and leather or electricity :-))

First item to restore was the 88 valves which are the metal circles with the red guide going across. Each valve is made up of an upper and lower seat, 2 guides, valve stem, 4 leather valve seats, 4 metal retainers and 8 screws. Each individual valve is completely dismantles, new leather seats cut to the correct size and installed, They are then regulated for 1/32" movement, top seats installed and sealed. There are 88 of theses secondary valves and another 88 primary valves which will be shown in a few weeks. Because the job is repetative but taking a great deal of time few pictures were taken.

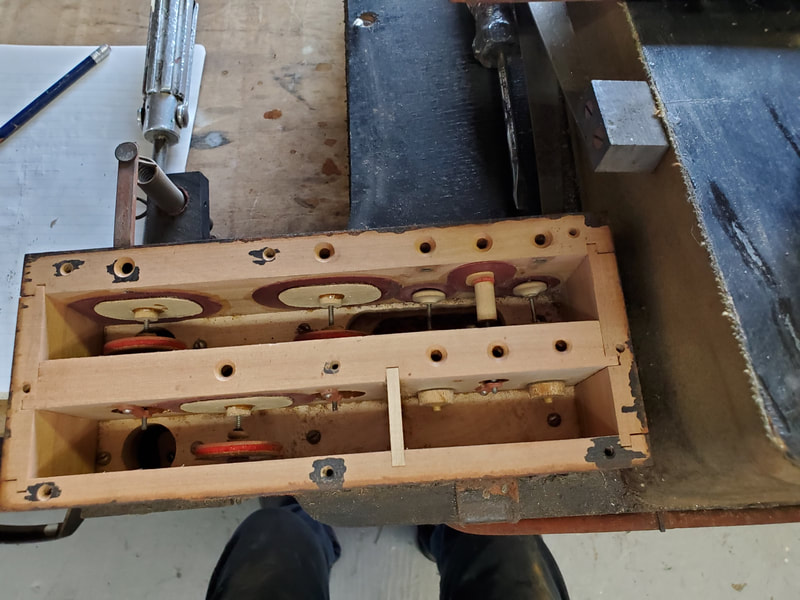

Next restoration work has moved to recovering the little finger pneumatics which are glued onto 3 seperate boards. These finger pneumatics are what actually plays the piano bu pushing up on the piano action exactly the way the piano key does when you push it down. These pneumatics are gluded using hot hyde glue. to remove the pneumatics I heat the glue with an iron to soften the glue which is now over 100 years old and with a scraper carefully remove the pneumatics. Then the old pneumatic cloth is removed on a sander, Pneumatics are then resealed to be air tight and new pneumatic cloth glued back on. This is done in three steps, first the front span end, then the two side panels and finall the pneumatic is closed with a clamp and the hinge end is glued and left over night to dry.

First item to restore was the 88 valves which are the metal circles with the red guide going across. Each valve is made up of an upper and lower seat, 2 guides, valve stem, 4 leather valve seats, 4 metal retainers and 8 screws. Each individual valve is completely dismantles, new leather seats cut to the correct size and installed, They are then regulated for 1/32" movement, top seats installed and sealed. There are 88 of theses secondary valves and another 88 primary valves which will be shown in a few weeks. Because the job is repetative but taking a great deal of time few pictures were taken.

Next restoration work has moved to recovering the little finger pneumatics which are glued onto 3 seperate boards. These finger pneumatics are what actually plays the piano bu pushing up on the piano action exactly the way the piano key does when you push it down. These pneumatics are gluded using hot hyde glue. to remove the pneumatics I heat the glue with an iron to soften the glue which is now over 100 years old and with a scraper carefully remove the pneumatics. Then the old pneumatic cloth is removed on a sander, Pneumatics are then resealed to be air tight and new pneumatic cloth glued back on. This is done in three steps, first the front span end, then the two side panels and finall the pneumatic is closed with a clamp and the hinge end is glued and left over night to dry.

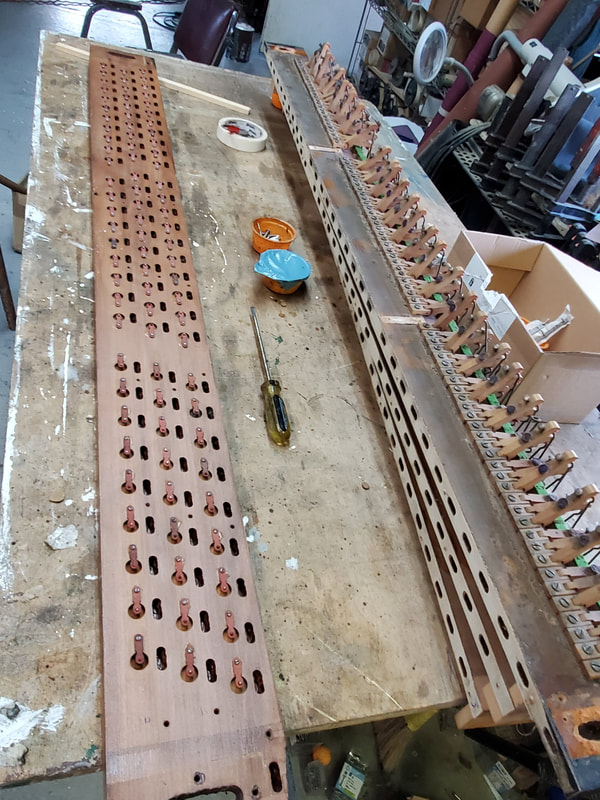

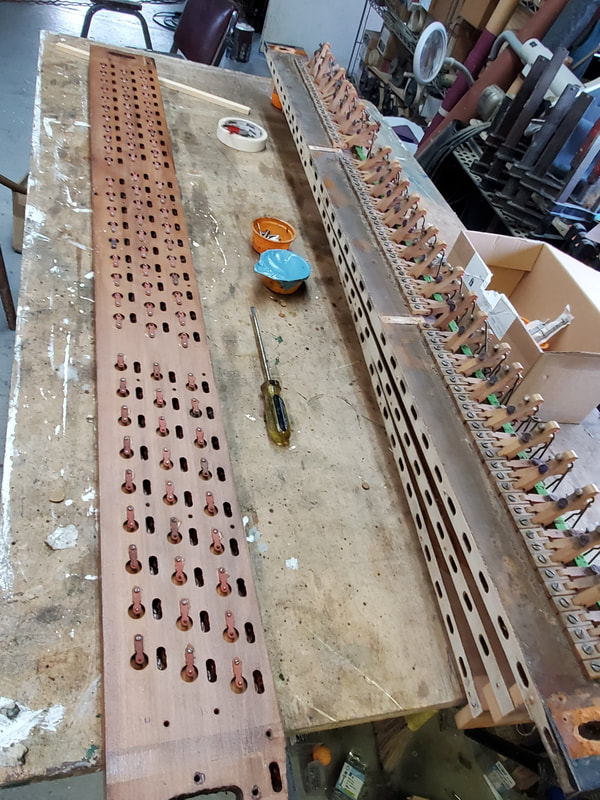

Oct 4 2021 Completion of the 88 pneumatic bellows and the assemblie of the 3 pneumatic shelves which are now ready to be assembled back to the valve box of the player stack.

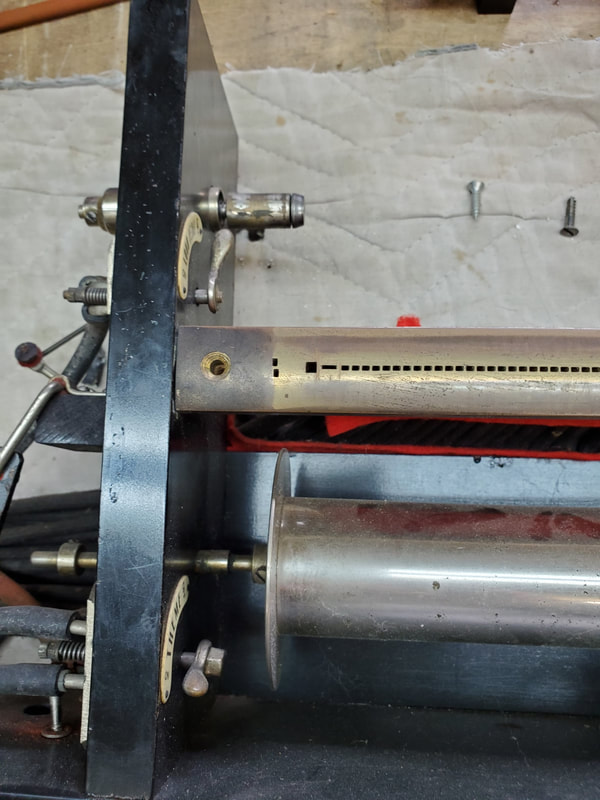

Oct 11/21 Assembly of the player piano stack lower section is now completed after the weeks of working on the many different parts it is finally going back together. The old lead tubing was found to have turned to white powder inside even though having a cloth sleeve. This required the removal of the old tubing and plugging all of the 88 holes with hard wood then redrilling the correct size hole for a piece of brass tubing that the new tubing will fit on.

Now to move onto the spool box shelf with its tracking system, airmotor and to retube.

Pictures may not be in order of dissassemblie and to make larger just click on the actual picture.

Now to move onto the spool box shelf with its tracking system, airmotor and to retube.

Pictures may not be in order of dissassemblie and to make larger just click on the actual picture.

Oct 23/21 Work continues with the primary valves Replacing the old lead tubing with all new tubing, Air motor restoration and tracking system etc.